Resistive vs. Capacitive: Why TracSil™ Sensors Use Resistive for AI Motion Tracking

- wavecompany

- 2일 전

- 4분 분량

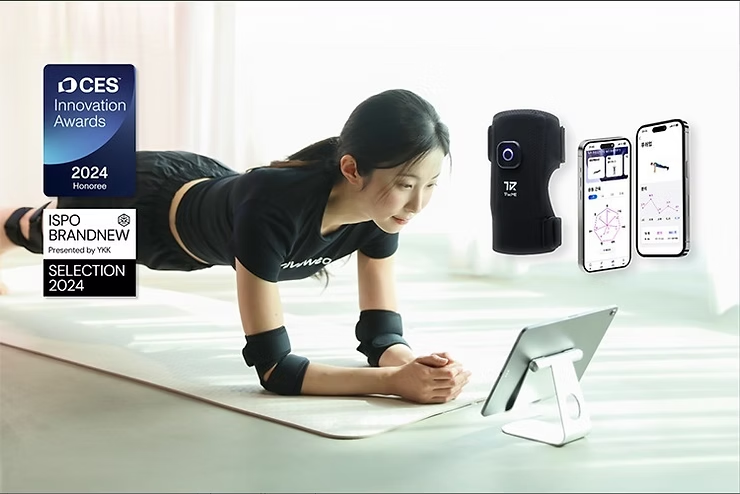

In the quest to perfectly quantify human movement, engineers face a fundamental choice in sensor technology. From smartwatches that count our steps to advanced robotic systems, sensors are the soul of the machine, translating physical actions into digital insights. Wave Company's TracSil™ technology, a stretchable silicone textile designed for movement tracking, represents a significant step forward in this field.

However, its effectiveness hinges on a critical engineering decision: the use of resistive sensors over their more complex counterpart, capacitive sensors. This post will explore the science behind that choice, examine how TracSil™ can interpret complex movements, and look ahead to its transformative applications.

The Core Choice: Robustness vs. Raw Sensitivity

At the heart of any motion tracking system is a sensor that translates movement into data. For flexible wearables, the two most common choices are resistive and capacitive sensors, each with distinct strengths and weaknesses. Here’s a breakdown of the technology and why TracSil™ uses a resistive system.

Capacitive Sensors: High Sensitivity, High Maintenance

Capacitive sensors are known for their precision, working by measuring changes in a surrounding electric field.

Pros: They are extremely sensitive, accurate, and can be made from a wide variety of flexible materials.

Cons: This sensitivity makes them vulnerable to real-world conditions. They can be disrupted by humidity, temperature changes, and especially by electromagnetic interference (EMI)—the electronic "noise" from other nearby devices. This requires complex and often costly shielding to ensure reliable readings.

Resistive Sensors: Real-World Reliability

Resistive sensors work on a simpler, more direct principle: their electrical resistance changes when they are stretched or pressed.

Pros: They are robust, less complex, and significantly less affected by environmental factors like EMI or sweat. This makes them ideal for use during intense activity.

Cons: They may offer less raw sensitivity compared to a capacitive sensor in a controlled lab setting.

The selection of a resistive system for TracSil™ is a deliberate trade-off. It prioritizes stability, washability, and real-world reliability over the lab-grade sensitivity of capacitive sensors, creating a more practical and robust tool for athletes and researchers. (Pressure Profile Systems, 2025)

The Geometry of Insight: How a "V" Measures Angles and Speed

This is where the genius of the TracSil™ design becomes clear. Instead of a complex array of multiple sensors, it uses a single, V-shaped sensor placed strategically over a joint. So, how does this one piece of conductive silicone translate its stretching into high-level kinematic data?

Step 1: Measuring Joint Angle with Stretch

Think of the V-shaped sensor as a smart rubber band. As a joint like your knee or elbow bends, the conductive silicone sensor stretches.

A slight bend stretches the sensor a little, causing a small change in its electrical resistance.

A full bend stretches the sensor much more, causing a large change in its electrical resistance.

Our AI system is trained to understand this relationship perfectly. It reads the precise resistance value in real-time and instantly translates it into an exact joint angle, measured in degrees.

Step 2: Calculating Movement Speed from Angle Changes

Once the system knows the joint angle, calculating speed is the next step. The AI analyzes not just the angle itself, but how fast that angle is changing.

It can instantly tell the difference between the rapid change of an explosive athletic movement (like a squat jump) and the slow, steady change of a controlled rehabilitation exercise. By tracking this rate of change, TracSil™ provides an accurate, real-time measurement of movement speed.

TracSil's website confirms this capability, stating its AI can recognize specific movements and detect anomalies, a process made possible by first mastering the estimation of these core variables from its unique sensor.

The Future is Flexible: A World of Applications

By providing a washable, durable, and reliable way to track movement without cameras or bulky IMU sensors, TracSil™ is poised for impact across numerous fields.

Exercise and Rehabilitation: Imagine a user receiving real-time feedback on their squat depth, running form, or the consistency of their physical therapy exercises. TracSil™ can automatically count exercise repetitions.

Daily Ergonomics: For occupations that involve repetitive tasks, TracSil™ could monitor movement patterns to identify and correct potentially harmful motions, reducing the risk of strain injuries.

Mechatronics and Wearable Robotics: As a flexible sensor skin, TracSil™ could provide feedback for controlling prosthetic limbs or advanced exoskeletons. This would allow for more natural and intuitive control, bridging the gap between human intent and robotic action.

Ultimately, the thoughtful engineering behind TracSil™, beginning with the choice of a robust resistive sensor, has created a platform with the potential to seamlessly integrate high-fidelity motion tracking into our daily lives, transforming how we approach everything from personal fitness to the next generation of robotics.

References

Dong, T., Gu, Y., Liu, T., & Pecht, M. (2021). Resistive and capacitive strain sensors based on customized compliant electrode: Comparison and their wearable applications. Sensors and Actuators A: Physical, 326, 112720. https://www.sciencedirect.com/science/article/abs/pii/S0924424721001837

Pressure Profile Systems. (2025, March 6). Strengths and limitations of capacitive tactile array sensors. https://pressureprofile.com/pps-insights/strengths-and-limitations-of-capacitive-tactile-array-sensors

WAVE Company TRACSIL TM | Stretchable printed sensor for movement tracking. (n.d.). Wave Company. https://www.wavecompany.net/tracsil

.png)

Comentarios